Features & Advantages

Super Fine Concrete surface Finish

Certified, low maintenance & fast delivery

Versatile and sustainable solution

-Plastic formwork reduces waste and environmental impact in construction.

-Lightweight design lowers transportation emissions during delivery and installation.

Simple, Productive & high strength

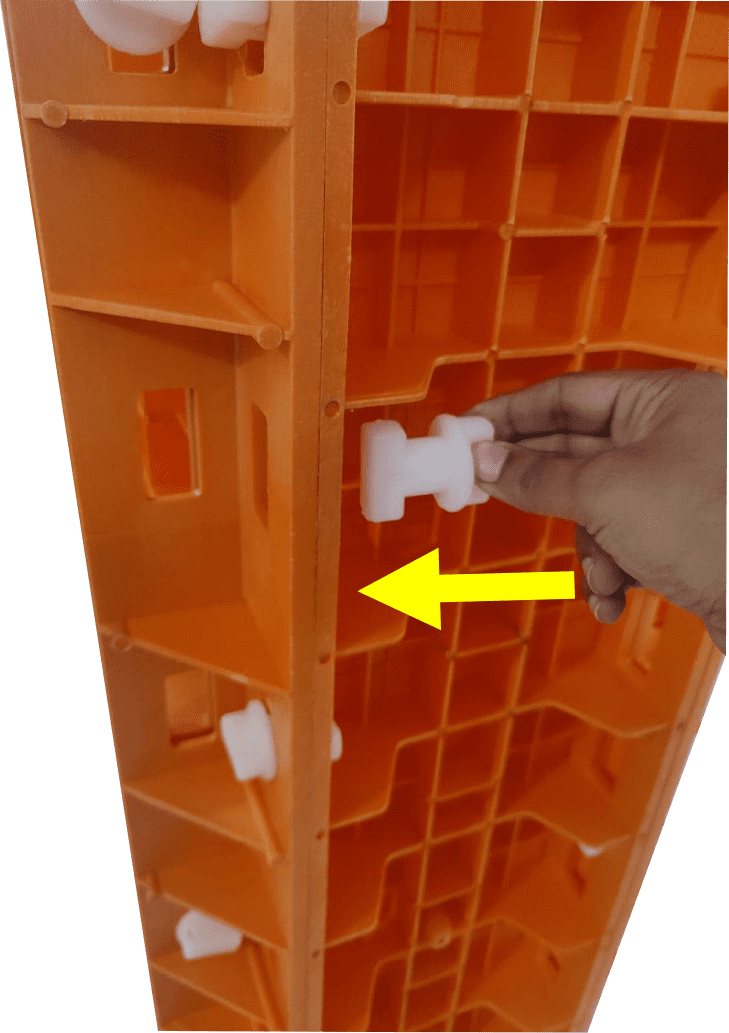

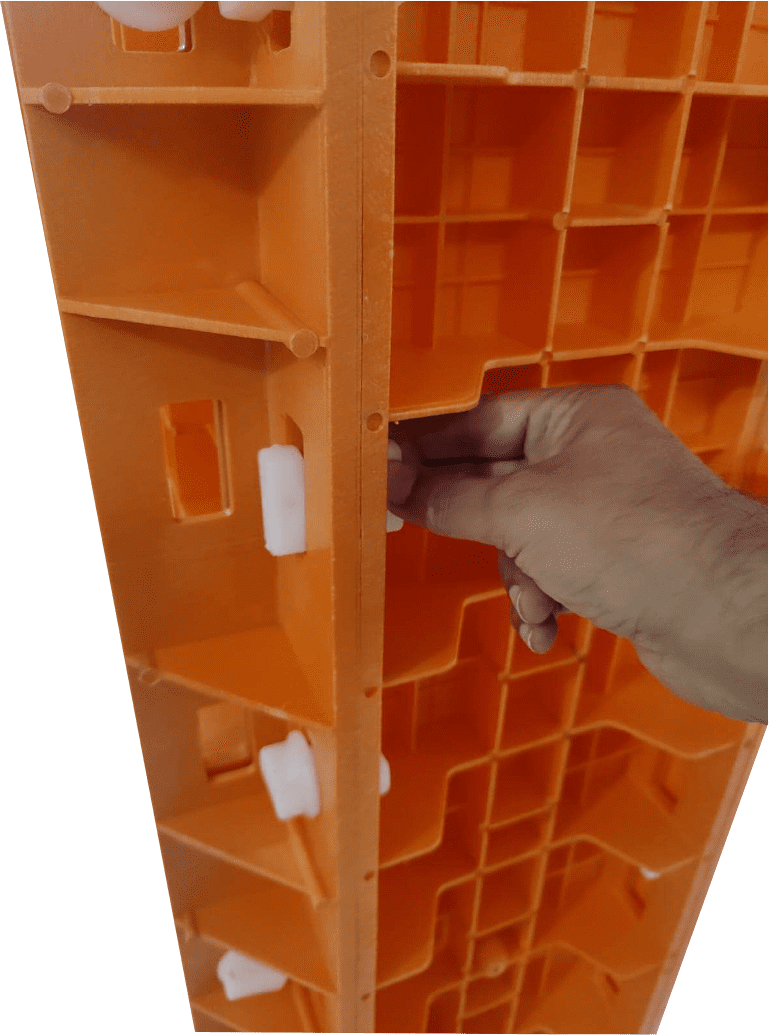

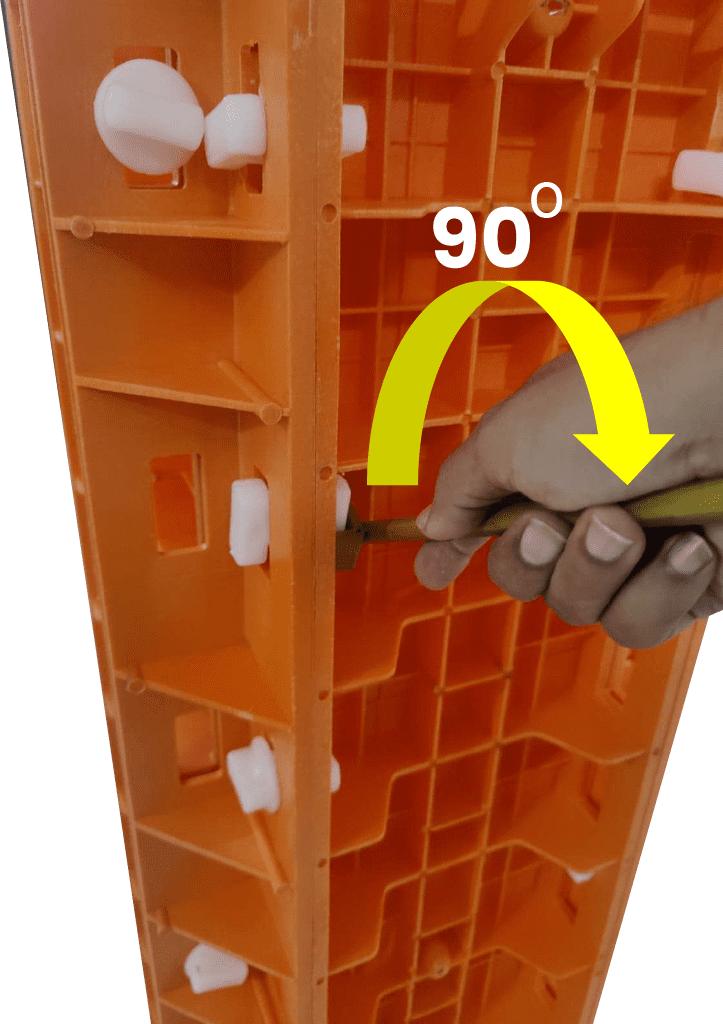

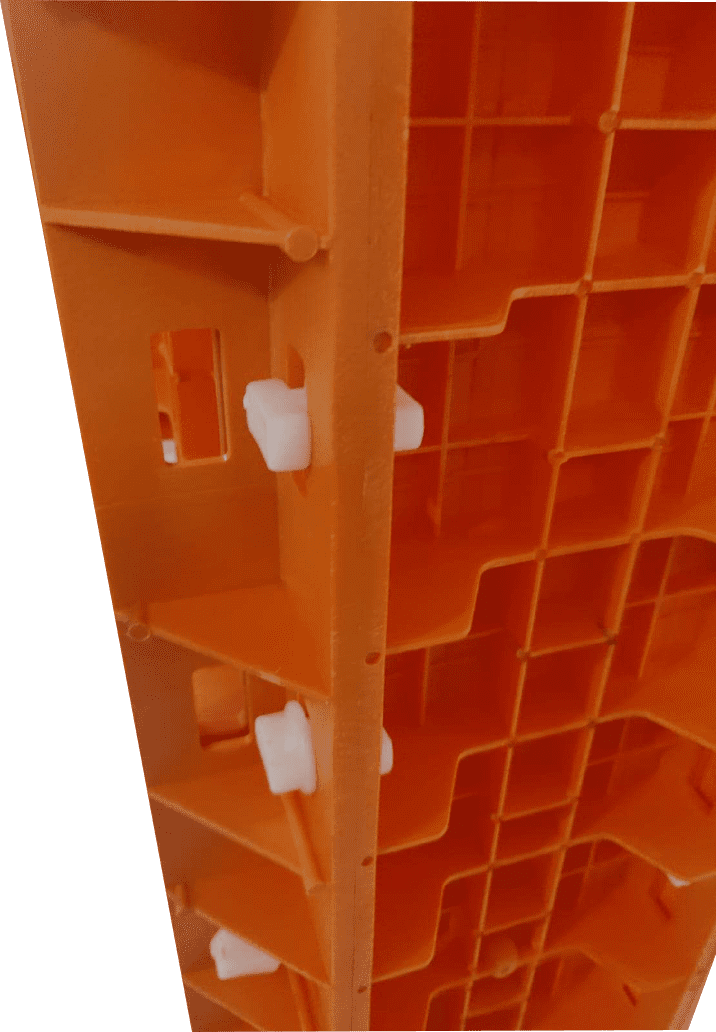

- Locking Pin are made of Nylon plastic, Easy and simple locking solutions

-High durability leads to longer service life, lowering maintenance costs and replacements

Sizes

Our Standard Modular Panels sizes to suit your requirements

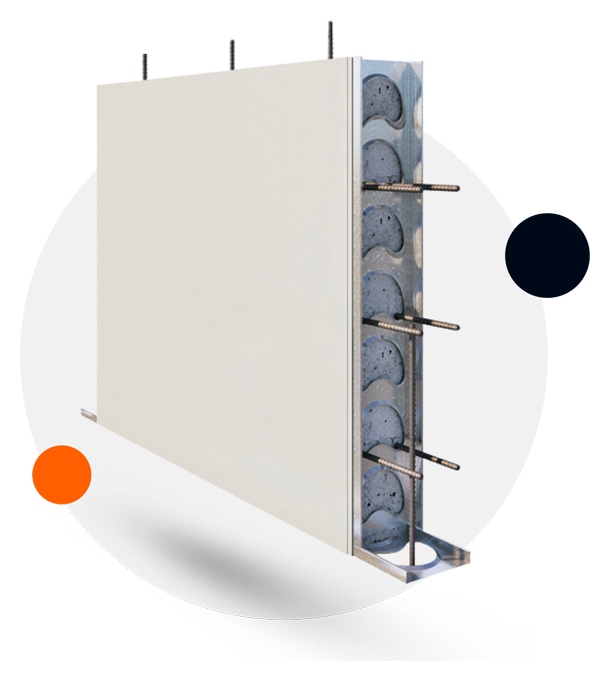

Our Plastic Formwork panels uniformly feature an 80mm standard thickness. They are reinforced with robust GI square pipe primary supports, capable of bearing loads of up to 5.5 tons per square meter. These panels are designed for compatibility with various sizes, offering flexibility and cost savings in inventory management.

| PANEL NAME | SIZE (INCH) | SIZE (MM) | WEIGHT (KGS) | AREA (SQ MTR) |

|---|---|---|---|---|

| 600 P | 24 x 48 | 600 x 1235 | 16 | 0.74 |

| 500 P | 20 x 48 | 500 x 1235 | 14 | 0.61 |

| 350 P | 14 x 48 | 350 x 1235 | 7.6 | 0.43 |

| 300 P | 12 x 48 | 300 x 1235 | 7.0 | 0.37 |

| 230 P | 9 x 48 | 230 x 1235 | 5.7 | 0.28 |

| 200 P | 8 x 48 | 200 x 1235 | 5.1 | 0.25 |

| 150 P | 6 x 48 | 150 x 1235 | 4.3 | 0.20 |

| 100 P | 4 x 48 | 100 x 1235 | 2.0 | 0.13 |

| IC 100 | 4 x 24 | 100 x 617 | 1.6 | 0.12 |

| OC 80 | 3 x 48 | 80 x 1235 | 1.3 | 0.1 |

Locking System

The standard locking pin for all panels

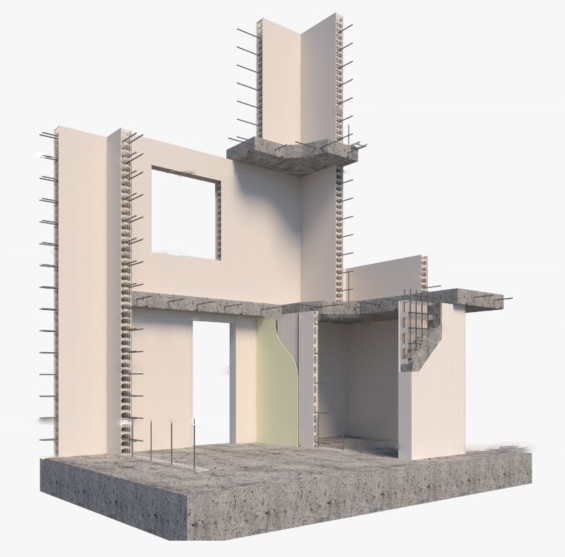

APPLICATIONS

Customised panels to suit your projects

Columns

- Achieve robust and accurate column structures effortlessly using customizable panels that guarantee proper alignment.

- Now it's feasible to cast larger-sized columns using panels of a smaller size

- Super Fine Finish of concrete surface with no honeycombs

Walls

- - An independent wall meeting Indian building code standards for structural, fire, and acoustic criteria.

- A robust reinforced concrete wall ensuring occupant security and superior quality.

- Resilient and durable substrate for finishing touches.

- Optimized thickness for efficient space utilization.

Lift walls

- -Best formwork system to build lift walls and Duct walls for aligned and perfectly straight walls

- Reduces construction material wastage

Slabs

- A practical and efficient system.

- -Simple handling and setup with interlocking design for precise alignment and support during concrete pouring, resulting in the creation of smooth and robust slabs

- Ideal for Capital Slabs, PT slabs, Flat Slab .

Boundary walls

- Perfect for challenging material access during wall construction and finishing.

- The substrate delivers a clean finish, even in its raw state.

Bridges

- Constructing bridge columns and walls stands out as one of the most demanding aspects in infrastructure development. Plastic formwork, crafted from materials resistant to rust and water, emerges as an effective solution

- The plastic formwork shuttering has demonstrated its excellence as the preferred system for erecting bridges, tanks, elevated storage reservoirs, sewerage treatment plants, and ETP tanks

CONSTRUCTION PROCESS

Design, specify and build with Plastic Formwork

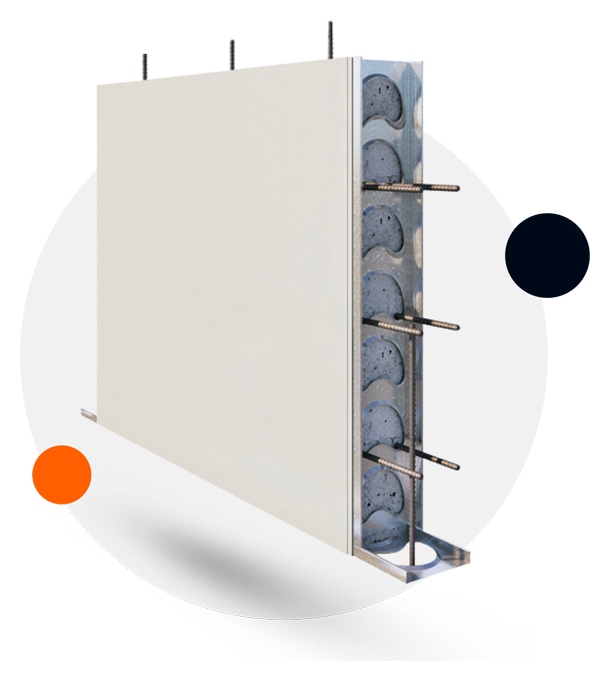

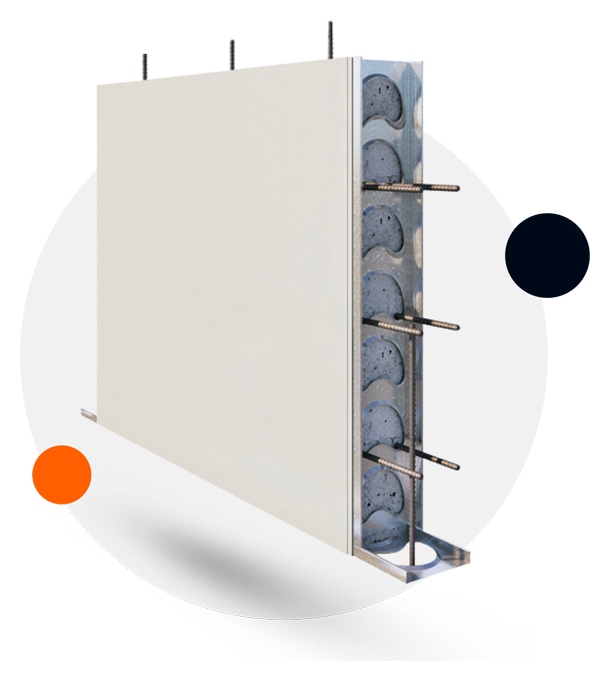

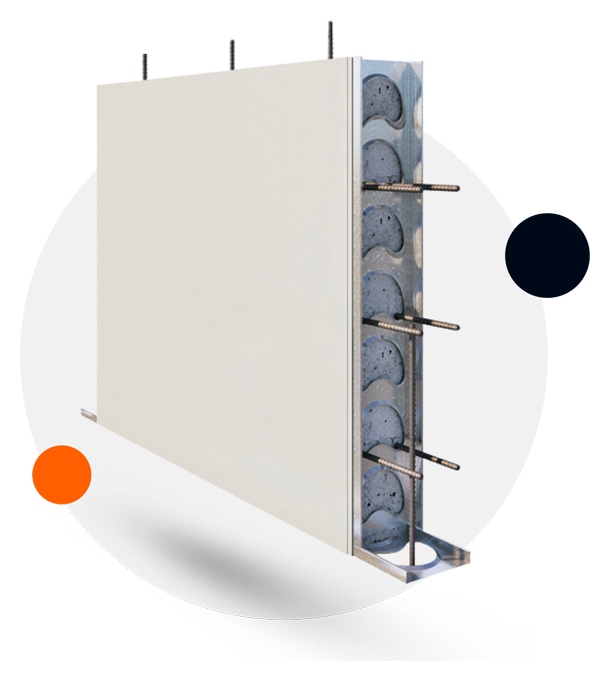

Plastic Formwork is the permanent formwork system that has changed the way architects and engineers approach prefabricated building design. A fully compliant deep-beam-functioning concrete walling system, Plastic Formwork is ideal for a myriad of commercial interior and exterior applications.

Our System Specification Finder and Resource Centre have all of the resources required to get you started and our friendly Customer Service Team are always happy to help.

NOTE: It is the responsibility of those using and designing with PlastoformSystems such as Logicwall® and Rediwall®, including but not limited to builders, designers, consultants and engineers to ensure that the use/application of product is compliant with all relevant National Construction Code (NCC), Standards and local Authorities having jurisdiction requirements such as, but not limited to structural adequacy, acoustic, fire resistance / combustibility, thermal, and weather tightness provisions. Contact us should you require further clarification.

Our team can help you with a full estimation.

| Features | Full Estimate |

|---|---|

| Walls scoped and marked up by PlastoformAccount/Sales Manager | |

| Walls scoped and marked up by PlastoformEstimators for Quantity Surveyor | |

| BOQ produced panels and accessories | |

| Supply quote produced (to Builder) | |

| Installer quote produced | |

| Turnaround time | 4 Business Days (priority service and revisions) - 6 Business Days (standard service) |

Plastic Formwork is delivered from our NSW site to you.

Delivered in cut to measure lengths, Plastic Formwork can be delivered to site within 8 business days of shop drawing approval.

Plastic Formwork permanent formwork wall installation

To ensure the highest quality installation of Plastic Formwork in your project, engage Plastoformrecommended installers.

Plastic Formwork recommended installers are regularly audited and fully trained in the construction methodology of our Plastic Formwork product. At the conclusion of the audit process, our recommended installers are issued with a Certification of Installation Conformity, confirming that their practices conform with our recommended installation of the product.

Installation

Following set out, Plastic Formwork panels are hand lifted into place over a steel floor track and starter bars.

Reo and services

The panels are braced using adjustable braces, then plumbed and straightened. Simple single or double reinforcement options can be installed horizontally and vertically, and electrical services can be accommodated within the walls.

Core filling

The panels are then core filled by pumping concrete (in accordance with the Plastoformlogicwall concrete mix design specification), usually performed from the formed deck of the next slab or off a scaffold.

Plastoformis there to support you every step of the way with industry leading sales and after sales support services.

As one of Australia's leading permanent formwork companies, we offer a range of professional services that help to enhance the efficiency provided by Plastic Formwork products including:

- Technical and after sales support

- Complimentary product and installation training

- Free thermal imaging inspection service

- Free Plastoformlogicwall® recycling services

Our in-house design team of structural engineers and estimators can undertake an obligation-free structure scheme and cost comparison for your project.

We can show how Plastic Formwork is able to improve structural efficiencies whilst lowering construction costs for your projects through:

- Smaller structural footprints

- Greater efficiency in load-bearing walls

- Reduced cranage and materials handling

- Reduced project program from speed of construction

To arrange your obligation-free structure scheme and cost comparison for your project, contact Plastoformtoday.