Future of Concrete Construction in INDIA

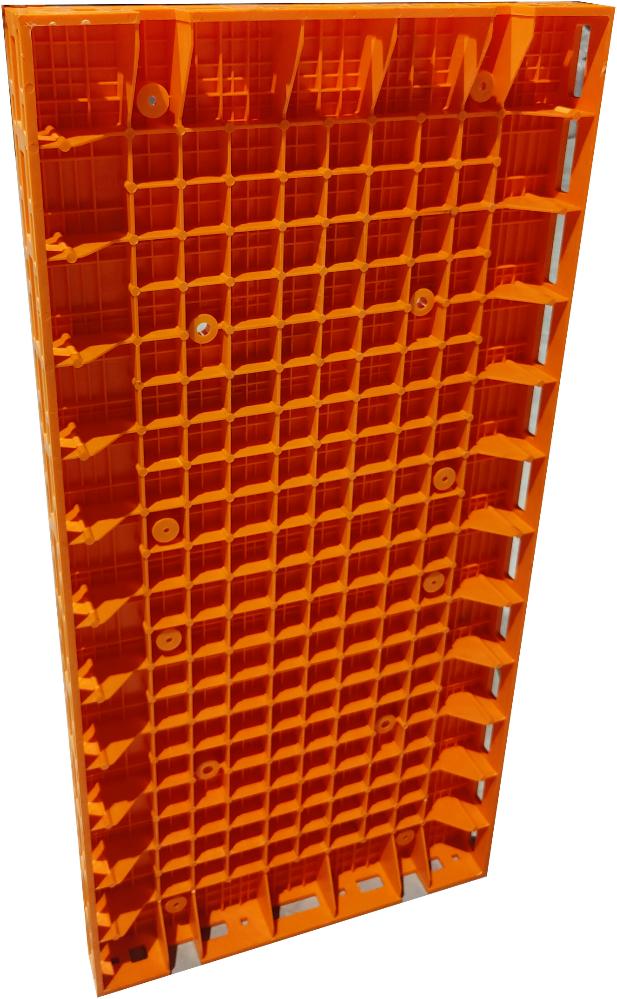

In the world of construction, the use of formwork is crucial for shaping and molding concrete structures until they achieve their desired strength. Traditional formwork materials, such as timber, steel, and aluminum, have long been used in the industry. However, the emergence of plastic formwork has revolutionized the way construction is done. Plastic formwork, made from materials like ABS or PP with fiberglass, offers a lighter, more durable, and cost-effective alternative to traditional formwork systems.

Understanding Plastic Formwork

Plastic formwork is a new and innovative category of formwork that is manufactured using a particular type of plastic, it is predominantly used for concrete structures due to its non-reactive nature towards different structural materials. Plastic formwork is chemically inert, meaning it does not have any adverse effects when combined with other substances specially cement. This characteristic makes it an ideal choice for concrete construction.

Plastic formwork offers numerous advantages compared to Plywood and MS Metal based formwork materials. It is durable, cost-effective, and highly flexible, providing construction professionals with a versatile solution for their projects. Additionally, plastic formwork is recyclable, making it an environmentally friendly choice.

Key Features and Benefits of Plastic Formwork

- Light weight

- No honeycomb

- Saves Labor, Time and Money

- Faster Erection and dismantling process

- No Plastering required

- 100+ Repetition

- Modular System means Zero Wastage

- 100% Recyclable after use

1. Durability and Strength

One of the primary advantages of plastic formwork is its high strength and durability. Made from polymer materials, plastic formwork is lightweight yet incredibly strong.

It can take a load of 5Tons/SqMtr and we can construct a 3.6 mtrs height wall in one go. Making it best suitable for Retaining wall, lift walls, bunkers. It exhibits excellent toughness, allowing for easy stacking and handling operations. Moreover, plastic formwork possesses Electricial and fire resistance, high insulation, moisture resistance, and acid and alkali corrosion resistance, making it suitable for various construction environments.

2. Reusability and Cost Efficiency

Plastic formwork is designed for long-term use, with a turnover rate of more than 100 times. It can be utilized multiple times, reducing the need for frequent replacements. This reusability factor significantly contributes to cost efficiency in construction projects. Although the initial investment in plastic formwork is higher compared to Plywood and Metal based shuttering and similar to Mivan type Aluminum based formwork, its long-term usability and recyclability make it a more economical choice in the long run.

3. Easy Installation and Demolding (Shuttering and DE shuttering)

Plastic formwork offers unmatched convenience during installation and demolding processes. Its surface is smooth and flat, eliminating the need for mold release agents. Unlike wood plywood, which requires surface treatment after a few uses, plastic formwork maintains its smooth surface throughout multiple applications. After the concrete is poured and solidified, the formwork can be easily separated from the structure, simplifying the demolding process.

All the locking system are made of plastic, so no consumables on construction site, eliminating repeated procurement, stock maintenance, chance of theft etc.

4. Environmental Friendliness

Plastic formwork stands out as an eco-friendly alternative to traditional formwork materials. It can be recycled, reducing environmental pollution and minimizing the impact on natural resources. Unlike wood, which contributes to deforestation, plastic formwork provides a sustainable solution for the construction industry. Additionally, plastic formwork does not release harmful volatile organic compounds (VOCs) into the environment, ensuring a safer and healthier working environment for construction workers.

For Example: If one plywood formwork is used for max 5 repetition, when though it is cheap, for 100 repetition we need to make a purchase atleast 20 times. But plastic is double the plywood cost and can be used 100+ times without a need to purchase again n again.

5. Versatility and Adaptability

Plastic formwork is highly versatile and adaptable to various construction requirements. It has different sized panel from 100mm (4 inch) to 600 mm (24 Inch) and using these panels can combination can be formed lowering the inventory cost. It can be used for a wide range of concrete applicatoins, including walls, columns, slabs, and even in specialized applications like boundary walls and drainage systems. The modular design of plastic formwork allows for easy customization and adjustments, enabling construction professionals to create complex shapes and forms with ease.

Comparing Plastic Formwork with Other Materials

When comparing plastic formwork with traditional formwork materials like plywood and steel, several factors come into play. While each material has its advantages and disadvantages, plastic formwork offers unique benefits that set it apart.

Plywood shuttering is a commonly used formwork material, but it has its limitations.

Plywood requires the following things

- Can cast max of 8 Ft height

- Carpenter on site

- Only 5-8 repetitions

- Electricity, Cutting machines, Nails and other consumables

- Runners (wooden battens) to ensemble on the site.

- Wastage of the material can vary from (10-20%)

- No skilled labour required

- Has no Scrap value

On the other hand, plastic formwork eliminates need of carpenter or skilled labour, No power tools required, almost 0% wastage, 25% scrap value, No consumables required. Plastic formwork also offers better durability and reusability(100+times), making it a more practical choice for construction projects

Sizes of the Panels

| PANEL | Width | Length | |

|---|---|---|---|

| P60 | 24 in | 600 mm | 1230 mm |

| P50 | 20 in | 500 mm | 1230 mm |

| P35 | 13.7 in | 350 mm | 1230 mm |

| P30 | 12 in | 300 mm | 1230 mm |

| P23 | 9 in | 230 mm | 1230 mm |

| P20 | 8 in | 200 mm | 1230 mm |

| P15 | 6 in | 150 mm | 1230 mm |

| P10 | 4 in | 100 mm | 1230 mm |

Plastic Formwork vs. Steel Formwork

Steel formwork is known for its strength and load-bearing capacity, but it lacks the flexibility and reusability of plastic formwork. Steel formwork is heavier and more challenging to handle, requiring specialized equipment for installation and removal.

It’s the most inefficient formwork system available in the market, the finish of the concrete surface is rough, and Lot of honeycomb are formed.

In contrast, plastic formwork is lightweight, easy to install, and can be demolded with minimal effort. It offers significant time savings during construction and ensures a labor-friendly process.

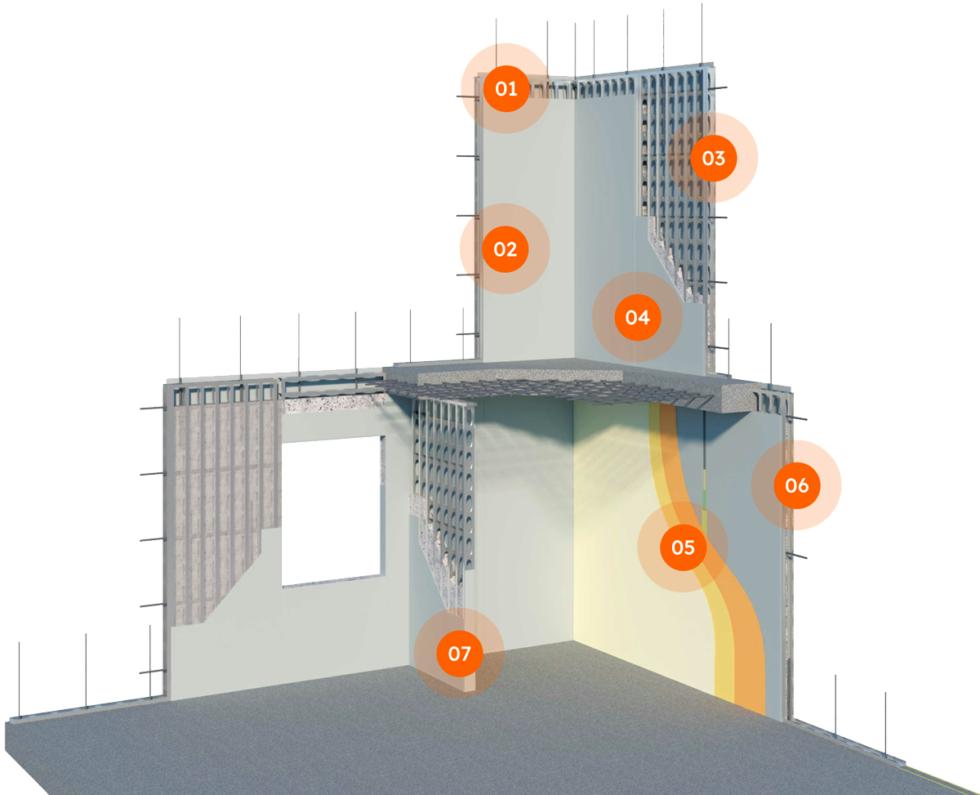

Applications of Plastic Formwork

Plastic formwork finds extensive application in various construction scenarios, offering unmatched versatility and adaptability. Some of the common applications of plastic formwork include:

Plywood shuttering is a commonly used formwork material, but it has its limitations.

Walls

Plastic formwork systems are used for constructing boundary walls, retaining walls, shear walls, and other types of concrete walls. The modular design of plastic formwork allows for quick and efficient wall construction.

Floors and Slabs

Plastic formwork is ideal for constructing concrete floors and slabs. Its lightweight nature and easy installation make it suitable for remote areas or projects with limited access to heavy construction machinery.

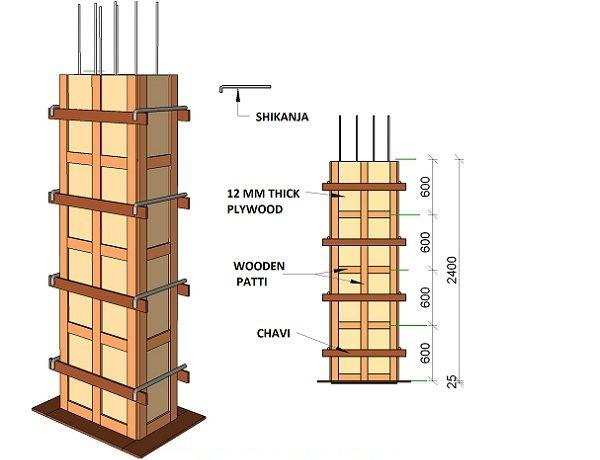

Columns

Plastic formwork systems are also used for constructing concrete columns. The flexibility and adaptability of plastic formwork enable the construction of various column sizes and shapes

Where to Find High-Quality Plastic Formwork

When it comes to high-quality plastic formwork, Plastoform Solutions should be your popular choice.

With a comprehensive range of plastic formwork sizes, we offers durable and reliable solutions for all types of construction projects. Our plastic formwork systems are designed for ease of use, cost efficiency, and environmental sustainability.

For more details Please contact us at info@plastoform.in or Call us +91 9581005050

Latest Blog

In the world of construction, the use of formwork is crucial for shaping and molding concrete structures

One of the primary advantages of plastic formwork is its high strength and durability. Made from..

When comparing plastic formwork with traditional formwork materials like plywood and steel...

Plastic formwork finds extensive application in various construction scenarios, offering..

Plastic formwork finds extensive application in various construction scenarios, offering..