Comparing Plastic Formwork with Other Materials

When comparing plastic formwork with traditional formwork materials like plywood and steel, several factors come into play. While each material has its advantages and disadvantages, plastic formwork offers unique benefits that set it apart.

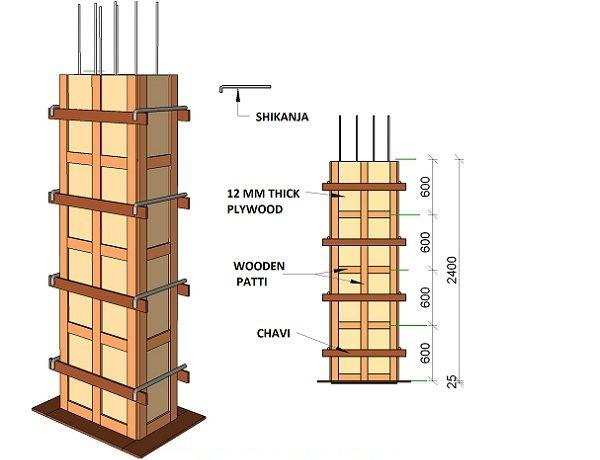

Plywood shuttering is a commonly used formwork material, but it has its limitations.

Plywood requires the following things

- Can cast max of 8 Ft height

- Carpenter on site

- Only 5-8 repetitions

- Electricity, Cutting machines, Nails and other consumables

- Runners (wooden battens) to ensemble on the site.

- Wastage of the material can vary from (10-20%)

- No skilled labour required

- Has no Scrap value

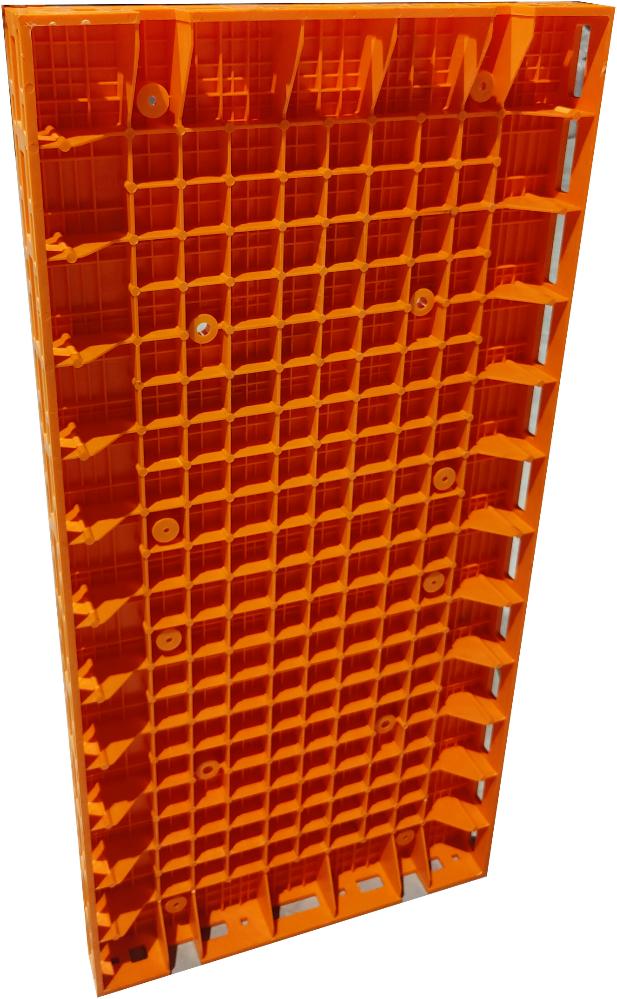

On the other hand, plastic formwork eliminates need of carpenter or skilled labour, No power tools required, almost 0% wastage, 25% scrap value, No consumables required. Plastic formwork also offers better durability and reusability(100+times), making it a more practical choice for construction projects

Sizes of the Panels

| PANEL | Width | Length | |

|---|---|---|---|

| P60 | 24 in | 600 mm | 1230 mm |

| P50 | 20 in | 500 mm | 1230 mm |

| P35 | 13.7 in | 350 mm | 1230 mm |

| P30 | 12 in | 300 mm | 1230 mm |

| P23 | 9 in | 230 mm | 1230 mm |

| P20 | 8 in | 200 mm | 1230 mm |

| P15 | 6 in | 150 mm | 1230 mm |

| P10 | 4 in | 100 mm | 1230 mm |

Plastic Formwork vs. Steel Formwork

Steel formwork is known for its strength and load-bearing capacity, but it lacks the flexibility and reusability of plastic formwork. Steel formwork is heavier and more challenging to handle, requiring specialized equipment for installation and removal.

It’s the most inefficient formwork system available in the market, the finish of the concrete surface is rough, and Lot of honeycomb are formed.

In contrast, plastic formwork is lightweight, easy to install, and can be demolded with minimal effort. It offers significant time savings during construction and ensures a labor-friendly process.

Latest Blog

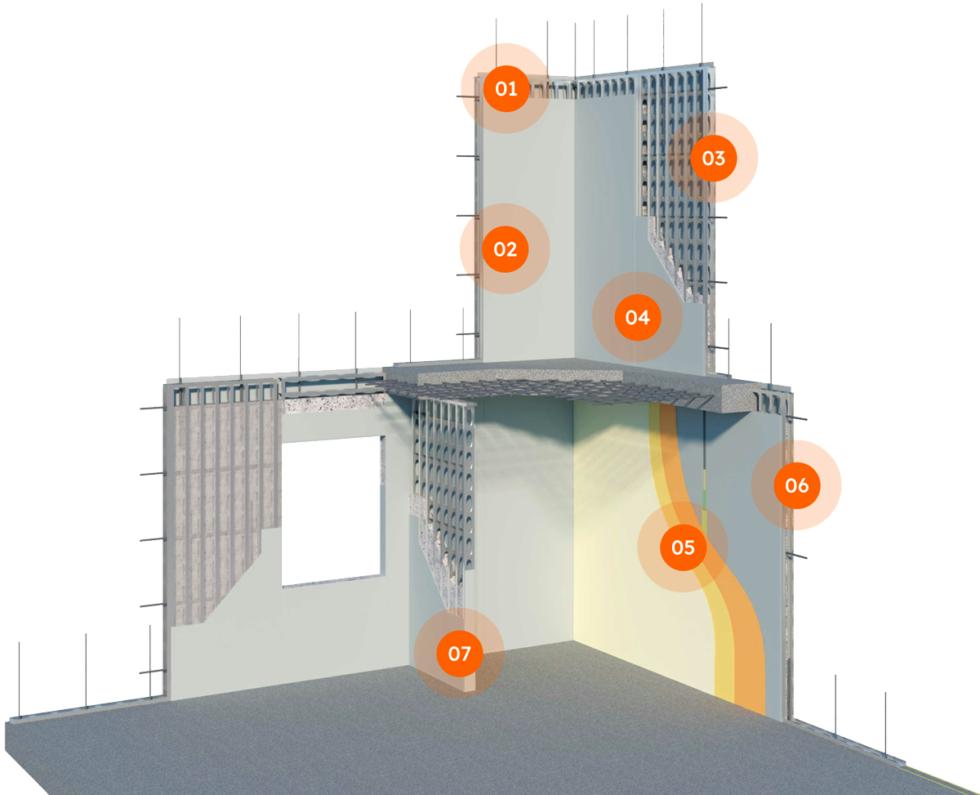

In the world of construction, the use of formwork is crucial for shaping and molding concrete structures

One of the primary advantages of plastic formwork is its high strength and durability. Made from..

When comparing plastic formwork with traditional formwork materials like plywood and steel...

Plastic formwork finds extensive application in various construction scenarios, offering..

Plastic formwork finds extensive application in various construction scenarios, offering..