Plastic Formwork vs Traditional Wooden Formwork: Which is Better?

Plastic formwork is transforming the construction industry by offering a more durable, reusable, and cost-effective alternative to traditional wooden formwork. If you're involved in construction, real estate development, or infrastructure projects, choosing the right formwork material can impact project efficiency, cost, and sustainability.

In this article, we’ll compare plastic formwork with traditional wooden formwork to help you determine the best option for your construction needs.

What is Plastic Formwork?

Plastic formwork is a lightweight, durable, and reusable system used in construction to shape concrete structures. Made from high-strength polypropylene (PP) or ABS plastic, it is designed to withstand repeated use while maintaining structural integrity.

Key Benefits of Plastic Formwork

✅ High Durability: Resistant to water, corrosion, and chemical exposure, making it ideal for all weather conditions.

✅ Lightweight and Easy to Handle: Reduces labor costs and speeds up installation.

✅ Multiple Reuses: Can be reused over 50 times, making it more cost-effective in the long run.

✅ Smooth Concrete Finish: Eliminates the need for additional plastering or surface treatments.

✅ Eco-Friendly: Made from 100% recyclable plastic, reducing environmental impact.

Common Applications of Plastic Formwork

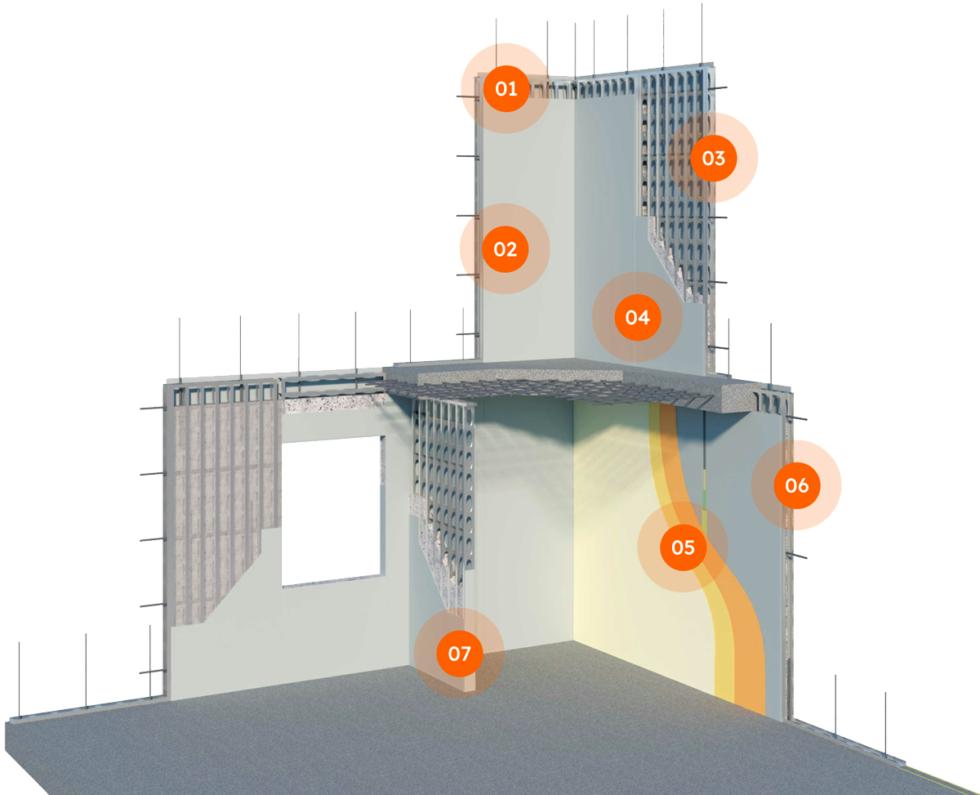

- High-rise buildings

- Residential and commercial structures

- Infrastructure projects (bridges, tunnels, highways)

- Complex architectural designs requiring precision and smooth finishes

What is Traditional Wooden Formwork?

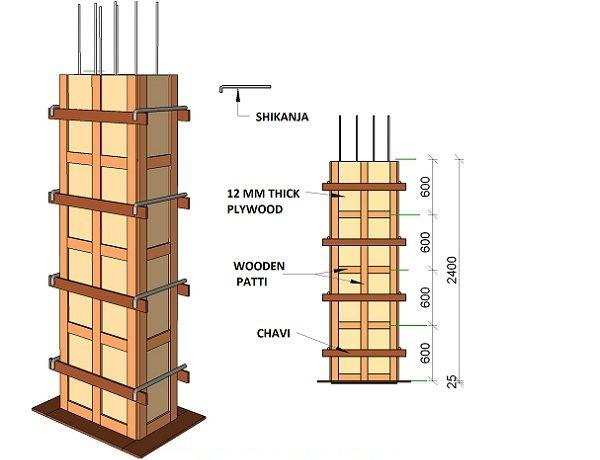

Traditional wooden formwork is made from timber or plywood, offering a flexible and customizable solution for shaping concrete. While it has been widely used in construction for decades, its limitations have led to the increasing popularity of plastic formwork.

Key Benefits of Wooden Formwork

✅ Low Initial Cost: Wooden formwork is more affordable upfront, making it a popular choice for small-scale projects.

✅ Easily Customizable: Can be cut and modified for intricate structures.

✅ Widely Available: Readily sourced from local suppliers.

Limitations of Wooden Formwork

❌ Short Lifespan: Can only be reused 5-10 times before it degrades.

❌ Water Absorption Issues: Wood absorbs moisture, leading to warping, swelling, and reduced strength.

❌ Heavy and Labor-Intensive: Requires more effort for assembly and transportation.

❌ Not Environmentally Friendly: Involves deforestation and generates significant construction waste.

Why is Plastic Formwork the Better Choice?

For modern construction, plastic formwork is the superior option due to its:

- Long lifespan and multiple reuses, reducing material waste.

- Faster installation and lower labor costs, improving overall efficiency.

- Better sustainability, as it is made from recyclable materials.

- Stronger resistance to weather conditions, making it ideal for all climates.

While wooden formwork may be suitable for one-time or low-budget projects, its short lifespan and high maintenance costs make plastic formwork the more economical and sustainable choice for large-scale and long-term construction projects.

Plastoform Solutions: Your Trusted Partner for Plastic Formwork

At Plastoform Solutions, we specialize in high-quality plastic formwork designed to enhance construction efficiency, reduce costs, and promote sustainability. With over 15 years of experience in the plastic molding and construction industry, we provide cutting-edge formwork solutions that meet the highest standards.

Why Choose Plastoform Solutions?

✔ State-of-the-Art Manufacturing Facility in Hyderabad

✔ Innovative and Customizable Formwork Solutions

✔ Durable, Reusable, and Cost-Effective Products

✔ Expert Guidance and Support for Construction Projects

Looking for premium plastic formwork solutions? Get in touch with Plastoform Solutions today and discover how our advanced formwork systems can revolutionize your construction projects!

Latest Blog

In the world of construction, the use of formwork is crucial for shaping and molding concrete structures

One of the primary advantages of plastic formwork is its high strength and durability. Made from..

When comparing plastic formwork with traditional formwork materials like plywood and steel...

Plastic formwork finds extensive application in various construction scenarios, offering..

Plastic formwork finds extensive application in various construction scenarios, offering..