Project Name

Kothari Group- Kokapet

Location

Kokopet, Opp MGIT college

Builder Name

Kothari Group

Architect / Structural Engineer

Zaki and Associates

Construction By

Self- Kothari Group

Date

(Start Date March 2023)- (End Date:ongoing project)

Area of the Projects

1,20,000 SFT

No of Floors

Basements (3), Ground + 11 Floors

Description:

It’s a high-rise commercial property in the upcoming district of Hyderabad, Kokapet is a thriving locality that seamlessly blends urban convenience with serene natural beauty. Its strategic location offers easy access to major hubs like Gachibowli and the IT corridor, making it an ideal choice for professionals. Kokapet is renowned for its tranquil surroundings, lush green landscapes, and a charming lake, providing a picturesque backdrop to everyday life. As a rapidly developing area, Kokapet boasts modern amenities, renowned educational institutions, and upscale shopping and dining options.

Drawings: attached drawings file in jpeg and png format in email

Plastic requirements: 500 Sqmtrs

Project Information:

Requirements

Kothari Group have been doing project all over Hyderabad and mostly with plywood based shuttering, when they got to know about our material, we provided them with an optimized solution for Columns, Retaining wall and Lift and Shear walls – all the vertical structures

Solutions

There requirement and our solutions are as follows

Retaining wall- Project involves creating 3 basement slabs and 36-ft walls. Each slab-to-slab wall height is 12 ft (3.6 m), spanning a total wall length of 240 meters.

We supplied a 360 sqmtrs Plastic Formwork System for the retaining wall. Our strategy: Casting 50 mtrs X 3.6 mtrs in a single day, achieving the 240 mtrs target per slab within a month.

Total repetition of plastic formwork material was 15 times

Columns: The project had 25 columns with 6 different sizes,

1050x1050 1200 X1200 300X600 700X900 1350 X1200 1350 X1350

The Plastoform formwork system features easily assembled and disassembled modular panels. Our offering includes a set of 5 column panels, averaging 7 repetitions per floor, totaling 91 repetitions across 14 storage building levels.

1350 X1350 column was combined with 1350 X1200 and 1200 X1200 to increase repetition

Total repetition of plastic formwork material was 91 times

-

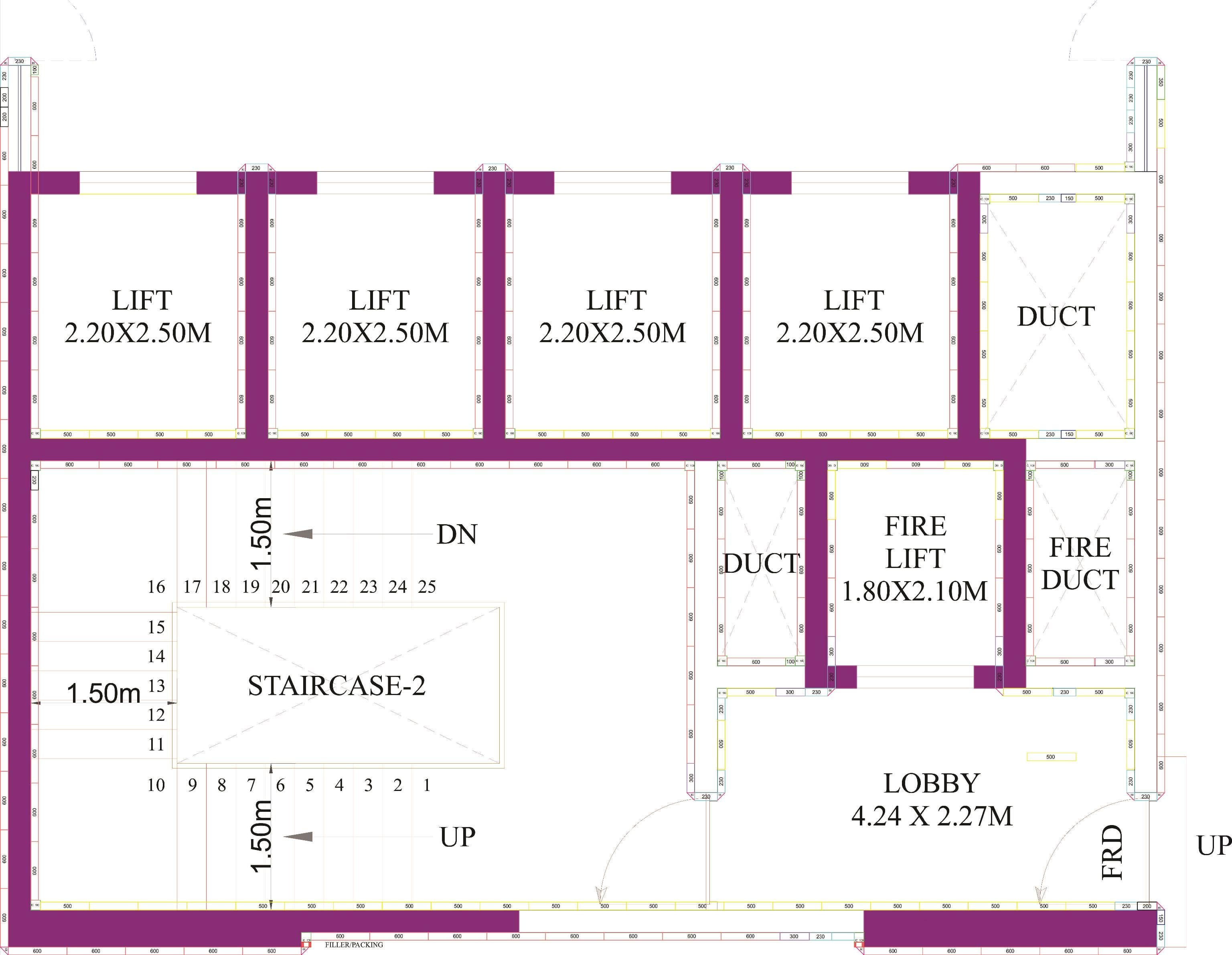

Walls: The project had 10 lift walls, 6 ventilation ducks and staircase walls on two end of the building - a typical arrangement of the building is as follows

Plastoform had designed and supplied formwork to cast the above typical setup in a single day With 2 repetition per floor slab. The lift and duct walls were executed flawlessly using plastic shuttering material

Total repetition of plastic formwork material was 30 times

Customer benefits:

Intricate concrete finishing.

50% of the formwork repetition achieved in one site

Huge cost saving – Plywood based shuttering costed them INR 200/Sqmtr, It was brought down to INR 55/ Sqmtr

Skilled Engineers - Saved on Skilled carpenters, QA and Skilled engineers to monitor the construction work