Choosing the Right Shuttering: The Advantages of Plastic Formwork Over Plywood Formwork

One of the most widely used construction technique is RCC based construction. Concrete which is semi-liquid state is poured onto reinforced steel bar to make Wall, column and Slab. The temporary support system that gives the required shape to concrete is called Formwork. Formwork is often called as Shuttering, Centering and Staging. The material used as formwork have also evolved over years, traditional wooden flanks, Mild Steel formwork and Plywood formwork. Plastic is one the new and innovative product that is more efficient and eco-friendly product that is replacing traditional old formwork material.

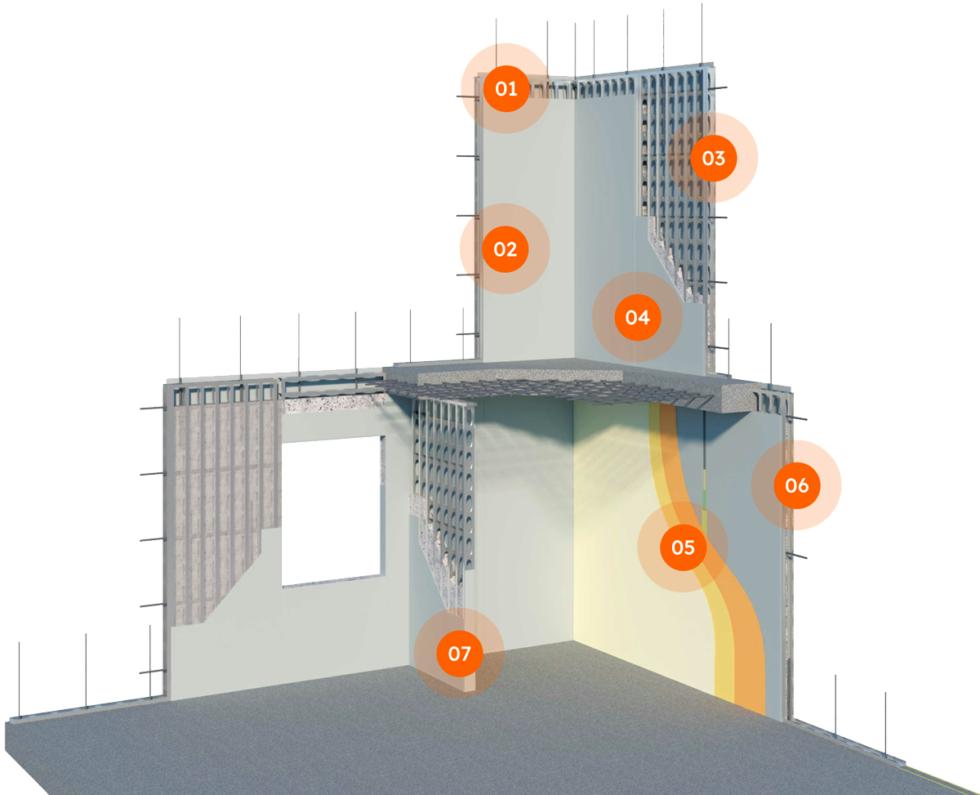

Image of traditional | MS steel | plywood shuttering

In this blog, we will do a deep dive and compare the two mostly widely used formwork system i.e., Plywood Shuttering and Plastic shuttering

Plastic is a very controversial word in this modern world, But it’s a boom to construction industry which is replacing the traditionally used timber, plywood which aren’t efficient and lead to deforestation.

Plastic formwork system are made of plastic panel with plastic locking system, these panel are 80mm thick (40 mm is plastic and 40 mm is GI reinforcement)

The Size of panel are below with standard height of 1235 mm (48 Inchs / 4 Feet) which can be extended to 2470 mm ( 8 Feet), 3000 mm (10 Feet) and 3695 mm (12 Feets)

- 600 mm (width) - 1235 mm, 2470 mm, 3700 mm (height)

- 500 mm (width) - 1235 mm, 2470 mm, 3700 mm (height)

- 350 mm (width) - 1235 mm, 2470 mm, 3700 mm (height)

- 300 mm (width) - 1235 mm, 2470 mm, 3700 mm (height)

- 230 mm (width) - 1235 mm, 2470 mm, 3700 mm (height)

- 200 mm (width) - 1235 mm, 2470 mm, 3700 mm (height)

- 150 mm (width) - 1235 mm, 2470 mm, 3700 mm (height)

- 100 mm (width) - 1235 mm, 2470 mm, 3700 mm (height)

- 10 mm (width) - 1235 mm, 2470 mm, 3700 mm (height)

- Inner Corner 80 X 1235 for 90-degree Locking

- Outer Corner 100 X 1235 for 270-degree Locking

All Panel can be connected to each other seamlessly and locked using plastic locking system. Some of the other benefits of PP formwork system are

- Light-Weight

- Easy to ensemble and dismantle

- 80-100 repetition

- 0% wastage on site

- No Carpenter required

- Modular Panel System

- 20 kgs per sqmtr Weight

- 100% recyclable after use

- 25% scrap value

Strength and Durability of PVC Shuttering

Plastic formwork are made of harden plastic material with an additional techno polymer mix to protect from UV.

Our Plastic formwork system is tested on various different parameters by experts in Civil and construction industry along with NABL certified Lab Reports

The Technical data of Plastic formwork system is below

- Allowable Bending Moment: 5.02 KN.M

- Shear Load: 11.4 KN

- Flexural Rigidity (EL Value): 455 KNm²

- Allowable Bearing Load: 49800 N

- Lateral Pressure due to Concrete: 52.5 KPA

Locking System: Locking system is made of Plastic Nylon Material and very easy to Lock and unlock, Plastoform’s Plastic formwork panels can be locked on all the four sides to any size panels using our locking key.

Just place the key in the locking position and twist of keys in 90 Degrees to LOCK and repeat the same in anticlock direction to UNLOCK

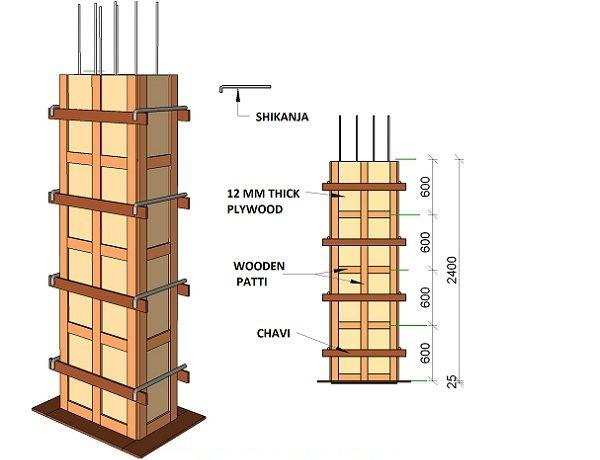

PLYWOOD BASED CONVENTIONAL FORMWORK SYSTEM

Plywood-based shuttering refers to a construction technique that involves using plywood sheets as formwork or molds for pouring and shaping concrete structures. Shuttering is an essential part of the concrete construction process, as it provides temporary support and containment for the wet concrete until it cures and gains sufficient strength.

Plywood-based shuttering involves the following steps:

Selection of Plywood: High-quality plywood is chosen for its durability, smooth surface, and ability to resist the moisture and pressure of the wet concrete.

Cutting and Assembly: Plywood sheets are cut to the desired sizes and shapes for the specific concrete structure being constructed. These sheets are then assembled and joined together using various techniques such as nails, screws, or clamps to create the formwork.

Accessories: Plywood is the main component, along with plywood we have Batten (Pine wood or equivalent) also known as wooden Patti/ wooden runner, Walers (chavi), Tie rods (Shikanja), Nails, Cutting machine and other power tools.

Comparison of plywood shuttering vs Plastic formwork

| Feature | Option 1 | Option 2 |

|---|---|---|

| Rate | 5500 INR/ SQMTR | 1100 INR / SQMTR |

| Repetitions | 80-100 | 5-10 |

| Cost/Repetitions | 55-70 INR/SQMTR | 220-110 INR/SQMTR |

| Weight | 20 Kgs/SQMTR | 22 Kgs/SQMTR |

| Wastage | <1% | 15-20% |

| Scrap Value | 20% | 0% |

| Skilled Labor | 1-2 | 5-10 |

| Onsite Work | 0% | 100% |

| Modularity | Yes | No |

In conclusion, Plywood based traditional style shuttering system is costly, labor-oriented and not eco-friendly and sustainable.

In 2025, when India is heading to become third largest economy with focus on infrastructure and development and the same time is committed to adapting Green building measures. Plastic formwork system could be a perfect way to reduce deforestation and move toward adaption new and innovative solutions in construction industry.

Plastic formwork system, PP formwork, PVC formwork, Plastic shuttering there are many names is eco-friendly, efficient and effective formwork system

Latest Blog

In the world of construction, the use of formwork is crucial for shaping and molding concrete structures

One of the primary advantages of plastic formwork is its high strength and durability. Made from..

When comparing plastic formwork with traditional formwork materials like plywood and steel...

Plastic formwork finds extensive application in various construction scenarios, offering..

Plastic formwork finds extensive application in various construction scenarios, offering..