Drain Formwork

What is Drain?

A drain is a channel, pipe, or structure designed to remove excess water or other liquids from an area. It directs water away to prevent flooding, waterlogging, or structural damage. Drains can be open (like roadside channels) or closed (like underground pipes).

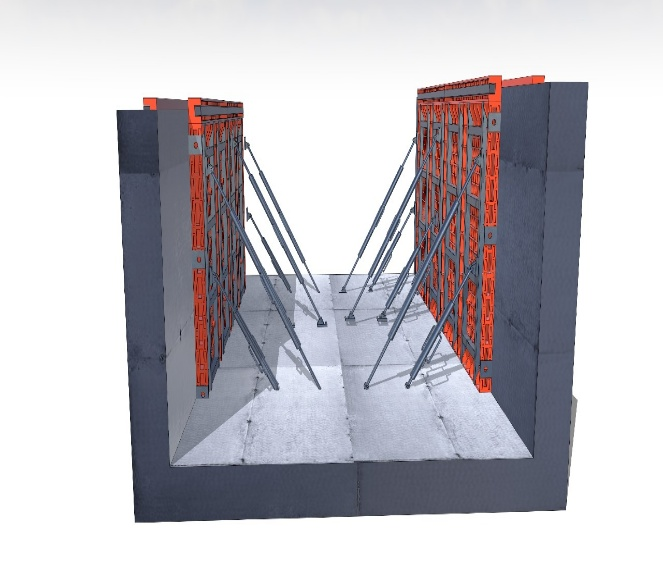

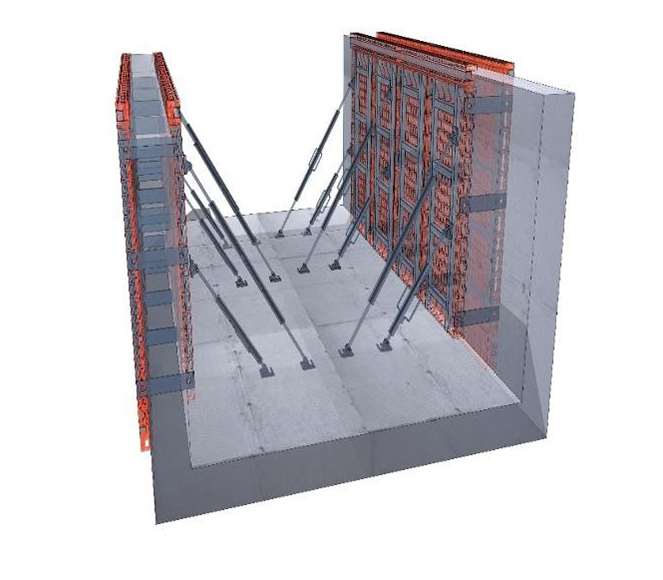

What is Drain Formwork?

Drain formwork is a specialized formwork system designed for constructing concrete drains and channels. It serves as a mold into which concrete is poured and shaped until it hardens, ensuring the drain structure has the correct dimensions, slope, and finish.

Where It Is Used

- Railways – drains are constructed alongside railway tracks to prevent water accumulation, which could weaken the track bed and cause operational hazards.

- Roadways – roadside drains channel rainwater away from the road surface, protecting the pavement and ensuring safe driving conditions.

- Irrigation – drainage channels help control the flow of water in agricultural fields, preventing over-irrigation and waterlogging.

- Sewage Channels – drains are essential for transporting domestic and industrial wastewater to treatment plants, maintaining sanitation and public health.

By Which Department It Is Constructed and Maintained

- Indian Railways Engineering Department

- National Highways Authority of India (NHAI)

- Public Works Department (PWD)

- State Irrigation Department & Water Supply and Sewerage Department

- Greater Hyderabad Municipal Corporation (GHMC)

Issues While Constructing a Drainage System

- Height and Size Variations

- Limited Working Space

- No Space for Outer Supports

- Remote Locations

- Material Theft

- Finishing Issues

- Labour Problems

- Weather Conditions

- Utility Interference

- Drainage Flow Management

Solutions to Drainage Construction Issues & How Plastic Formwork Helps

| Issue | Solution | How Plastic Formwork Helps |

|---|---|---|

| Height and Size Variations | Use adjustable formwork or systems that allow on-site size and height changes. | Plastic formwork is modular, allowing easy on-site modification of sizes and heights without new molds. |

| Limited Working Space | Utilize compact, lightweight materials and plan phased work for better space management. | Lightweight plastic panels are easy to handle and assemble even in tight or restricted spaces. |

| No Space for Outer Supports | Use formwork with built-in locking and tie systems to avoid the need for external supports. | Plastic formwork has a secure locking system and 4 built-in tie holes per panel; wall ties can also be used. |

| Remote Locations | Pre-fabricate components and optimize logistics for material transport and storage. | Plastic panels are lightweight and durable, making transport easier and reducing the need for frequent deliveries. |

| Material Theft | Secure storage and schedule deliveries close to use time. | Plastic formwork’s durability and reusability reduce replacement needs, minimizing losses from theft. |

| Finishing Issues | Use high-quality formwork that provides smooth surfaces for concrete casting. | Plastic formwork offers a smooth surface, resulting in excellent concrete finishes with minimal plastering. |

| Labour Problems | Use systems that require less skill and reduce labor intensity. | No skilled labor is required; panels have simple locking systems and are easy to assemble and handle. |

| Weather Conditions | Plan work to avoid bad weather; use protective measures for concrete curing. | Plastic formwork is weather resistant, maintaining integrity and quality during varying weather conditions. |

| Utility Interference | Conduct thorough site surveys and allow formwork adjustments on site. | Modular plastic formwork can be modified on site easily to fit around obstacles like utilities. |

| Drainage Flow Management | Use precise formwork systems that maintain correct slopes and alignments. | Plastic formwork’s modular design ensures accurate sizing and alignment, supporting proper drainage flow. |

Summary

Plastic formwork significantly improves drainage construction by being modular, reusable (100+ times), lightweight, and easy to handle. Its built-in locking system and tie holes eliminate the need for extensive external supports, making it ideal for limited spaces and remote locations. Leading plastic formwork manufacturers in Hyderabad, India are providing these innovative solutions that result in faster construction, lower labour skill requirements, and superior concrete finishes, effectively addressing many common site challenges.