Box Culvert

What is a Box Culvert?

A box culvert is a rectangular or square-shaped concrete structure used to allow water to pass through an embankment, road, railway, or other obstruction. It is typically made of reinforced concrete and is cast either on-site (cast-in-situ) or precast in factories. Box culverts are widely used for managing water flow under roads, railways, and pathways.

Where It Is Used:

- Roadways – to channel water under highways and prevent flooding.

- Railways – to allow drainage water or small streams to pass beneath railway tracks.

- Irrigation Canals – to allow water channels to cross paths or roads.

- Stormwater Management – for controlling runoff in urban areas.

- Underpasses – small pedestrian or vehicular underpasses also use box culvert designs.

- Pre-Cast culverts

Departments Involved:

- NHAI (National Highways Authority of India) – for culverts under national highways.

- PWD (Public Works Department) – for state roads and local crossings.

- Indian Railways Engineering Department – for railway culverts.

- Irrigation Departments – for culverts in canal systems.

- Municipal Corporations (e.g., GHMC) – for stormwater and urban drainage culverts.

Common Issues While Constructing a Box Culvert

- Heavy Lifting Requirements – Box culvert construction often uses large, heavy formwork or precast segments that require cranes and specialized equipment.

- High Reinforcement Density – Box culverts typically require a dense steel reinforcement cage, making placement, tying, and vibration of concrete difficult.

- Complex Jointing – For long spans or precast installations, proper alignment and sealing of joints is critical to prevent leakage.

- Groundwater Seepage – Excavated areas may face groundwater ingress, which complicates excavation and foundation stability.

- Traffic Management – Construction usually occurs under or near roadways/railways, requiring traffic diversion and safety measures.

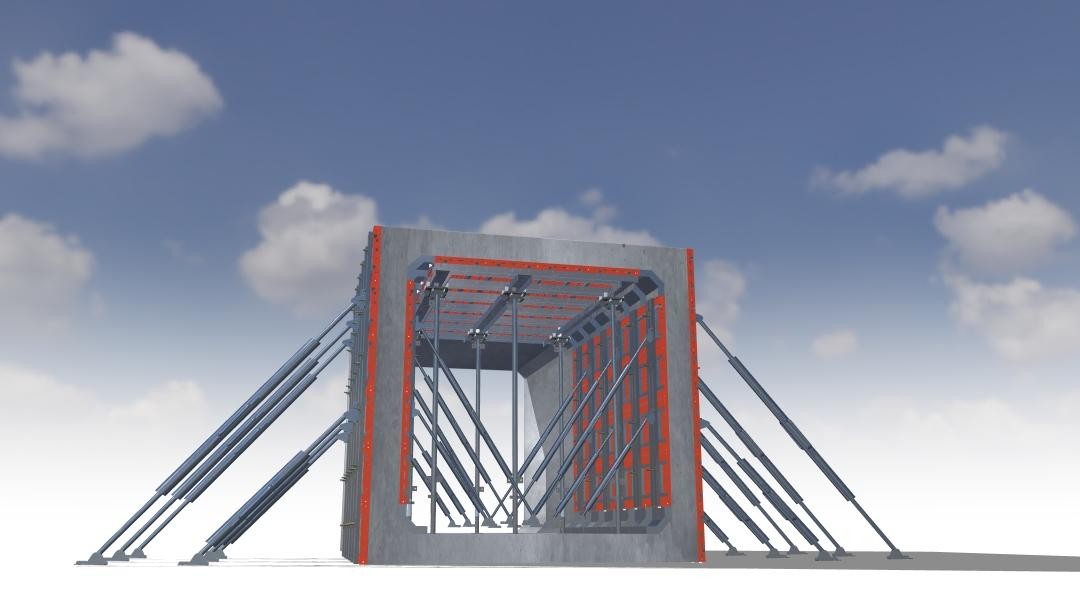

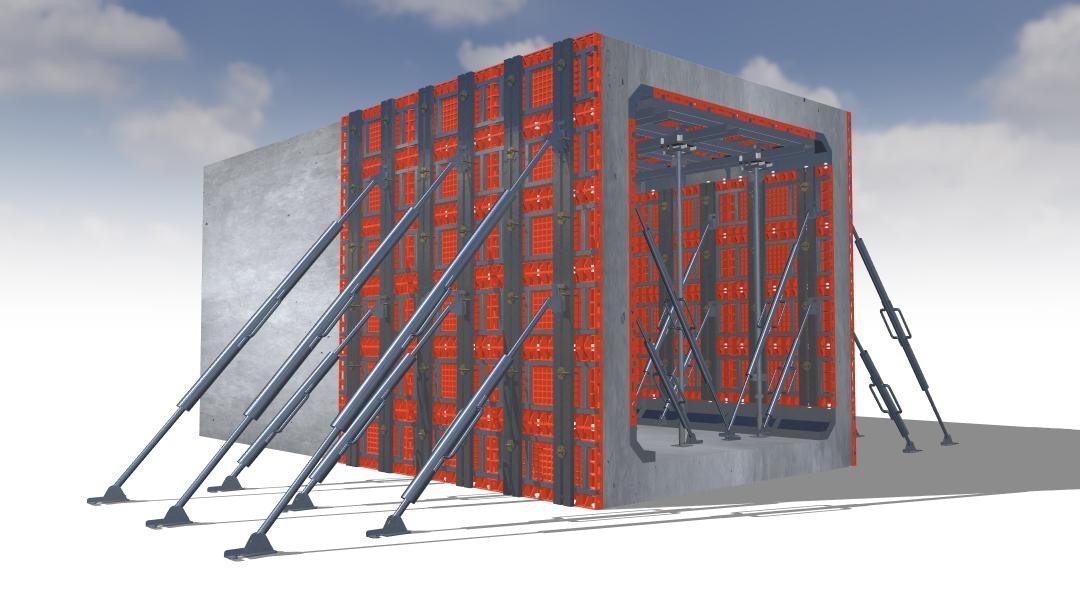

- Formwork Stability – The large vertical and horizontal loads during casting demand a rigid and stable formwork system to prevent collapse or deformation.

- Load Transfer During Construction – Temporary loads during casting and curing can create additional stresses, requiring careful shoring.

- Multiple Casting Stages – Larger culverts are built in segments, and managing the construction sequence (base slab → walls → top slab) can be challenging.

- Waterproofing Challenges – Ensuring watertightness in joints, construction seams, and around tie holes is critical.

- Restricted Working Height – Working inside the box during wall and slab casting can be cramped, affecting productivity.

- Structural Cracks – Improper curing, poor vibration, or inadequate reinforcement detailing can lead to shrinkage or structural cracks.

- Access for Equipment – Bringing machinery into confined or remote culvert construction sites is often difficult.

- Settlement Issues – Inadequate compaction under the base slab can lead to uneven settlement, affecting the culvert’s long-term performance.

- Backfilling Problems – Poor-quality or improperly compacted backfill around the culvert can cause erosion or failure.

- Coordination with Hydrology Design – Misalignment with natural flow patterns can lead to waterlogging upstream or downstream erosion.

- Formwork Removal Difficulty – Removing traditional heavy formwork from the inner walls and slab of the culvert is labour-intensive and risky.

- Long Curing Time – Box culverts often have thick sections requiring extended curing, which slows the construction schedule.

- Working in Remote/Underpasses – Culvert sites in rural or underpass locations may have limited lighting, power, and storage facilities.

- Environmental & Regulatory Compliance – Construction in watercourses or protected areas requires additional clearances and monitoring.

- High Project Costs – Due to complexity, equipment needs, and safety measures, box culvert construction is costlier compared to open drains.

Issues vs. How Plastic Formwork Solves Them in Box Culvert Construction

| Box Culvert Construction Issue | How Plastic Formwork Helps |

|---|---|

| Heavy Lifting Requirements | Plastic panels are lightweight and can be manually handled, reducing the need for heavy lifting equipment. |

| High Reinforcement Density | Modular panels fit easily around dense reinforcement cages, ensuring proper concrete placement without obstruction. |

| Complex Jointing | Modular design allows precise alignment, reducing joint gaps and simplifying sealing. |

| Groundwater Seepage During Excavation | Lightweight panels are easy to install quickly, minimizing site exposure time to groundwater. |

| Traffic Management Issues | Faster assembly/dismantling reduces disruption to traffic compared to traditional heavy shuttering. |

| Formwork Stability | Plastic formwork uses a secure locking system with 4 inbuilt tie holes per panel and wall tie compatibility, ensuring stability under loads. |

| Load Transfer During Casting | Built-in tie holes and wall ties provide robust load distribution without bulky external bracing. |

| Multiple Casting Stages | Easy dismantling and reassembly allow faster transition between base, wall, and slab casting. |

| Waterproofing Challenges | Precise jointing and smooth surface minimize honeycombing and leakage paths, improving watertightness. |

| Restricted Working Height | Lightweight panels can be installed and removed easily even in confined spaces. |

| Structural Cracks | A smooth non-absorbent surface ensures uniform curing and minimizes shrinkage cracks. |

| Access for Equipment | No need for cranes or large equipment for formwork handling, ideal for tight or remote sites. |

| Settlement Issues | Fast assembly reduces construction time, minimizing the risk of prolonged exposure to soil settlement. |

| Backfilling Problems | Panels can be quickly removed without disturbing the surrounding soil, ensuring proper backfilling. |

| Hydrology Coordination | Modular nature allows adjustments in slope and alignment during installation, matching design flow requirements. |

| Formwork Removal Difficulty | Simple locking system makes dismantling faster and safer compared to heavy steel or timber shuttering. |

| Long Curing Time | Panels can remain in place without damage, and easy reusability means no delays due to formwork shortages. |

| Remote/Underpass Working Conditions | Lightweight, easy-to-transport panels reduce logistics challenges in remote or low-access sites. |

| Environmental Compliance | Minimal site disturbance, no chemical coatings, and reusable panels make construction more eco-friendly. |

| High Project Costs | 100+ reuses, reduced labor needs, and faster construction lower the overall cost significantly. |

Summary – Role of Plastic Formwork in Box Culvert Construction

Box culvert construction faces several challenges such as heavy lifting requirements, dense reinforcement, groundwater seepage, restricted working space, alignment issues, and high costs. Traditional steel and timber formwork often make these problems worse due to their weight, complexity, and need for skilled labour.

Plastic formwork overcomes these challenges by offering:

- Modular and Adjustable Design – easily adapts to size or height changes on-site.

- Lightweight Handling – no cranes or heavy machinery required, ideal for remote or confined locations.

- Simple Locking System – with built-in tie holes and wall tie compatibility, ensuring stability without external bracing.

- Smooth Concrete Finish – reduces honeycombing and minimizes the need for plastering.

- Durability and Reusability – can be reused 100+ times, cutting material and project costs.

- Faster Construction – quick assembly and dismantling improve construction speed and reduce traffic disruption.

- Reduced Labor Dependence – no skilled labour required, making it easier to manage workforce shortages.

In conclusion, plastic formwork enhances speed, safety, quality, and cost-efficiency in box culvert construction while simplifying work in challenging conditions. Leading plastic formwork manufacturers in Hyderabad are driving this innovation, making modern construction more efficient and reliable.