Understanding Plastic Shuttering: Features, Benefits, and Applications

In the modern construction industry, plastic shuttering has revolutionized the way concrete structures are built. Traditional materials like wood and metal formwork have been used for decades, but they come with limitations such as high maintenance, limited reusability, and environmental concerns.

With its lightweight nature, durability, and cost-effectiveness, plastic shuttering is now the preferred choice for builders, contractors, and engineers. In this blog, we’ll take an in-depth look at what plastic shuttering is, its key features, benefits, and applications in construction.

What is Plastic Shuttering?

Plastic shuttering is a reusable formwork system made from high-quality plastic materials that provide a strong and smooth mold for concrete structures. Unlike traditional formwork, plastic shuttering is lightweight, water-resistant, and eco-friendly, making it a cost-effective and sustainable solution for modern construction projects.

Why is Plastic Shuttering Gaining Popularity?

- High durability and multiple reuses (can be used over 100 times).

- Waterproof and weather-resistant, unlike wood shuttering.

- Easy to install and dismantle, reducing labor costs.

- Eco-friendly, as it eliminates the need for deforestation.

Now, let’s explore the key features of plastic shuttering that make it the best alternative to conventional formwork systems.

Key Features of Plastic Shuttering

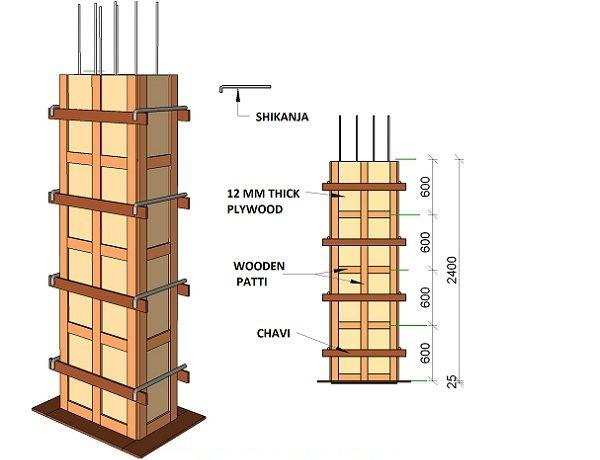

1. Lightweight and Easy to Handle

Plastic shuttering is much lighter than wooden or metal formwork, making it easier to transport, install, and remove without the need for heavy machinery. This reduces construction time and labor efforts.

2. High Durability and Reusability

One of the biggest advantages of plastic shuttering is its long lifespan. While wooden shuttering wears out after 5-10 uses, plastic shuttering can be reused more than 100 times, reducing material costs over time.

3. Water-Resistant and Weatherproof

Unlike wooden formwork, which absorbs moisture and deteriorates, plastic shuttering is completely waterproof and resistant to extreme weather conditions, making it ideal for humid and rainy environments.

4. Smooth Concrete Finish

Plastic shuttering provides a seamless surface, eliminating the need for extra plastering or finishing. This ensures a high-quality end result, saving both time and costs.

5. Eco-Friendly and Sustainable

Since plastic shuttering is reusable and recyclable, it is a more sustainable option compared to wood, which contributes to deforestation. Many construction companies now prefer plastic shuttering as part of their green building initiatives.

Benefits of Using Plastic Shuttering in Construction

1. Cost-Effective Over Time

Although the initial investment in plastic shuttering may be slightly higher than wood, its long-term cost-effectiveness comes from its multiple reusability and durability, making it a profitable choice for construction companies.

2. Faster Construction and Labor Efficiency

Due to its lightweight and modular design, plastic shuttering significantly reduces assembly and dismantling time, allowing faster project completion and reduced labor costs.

3. Improved Structural Quality

Plastic shuttering ensures precise formwork with minimal deformation, leading to stronger, more durable concrete structures.

4. Low Maintenance and Chemical Resistance

Unlike wood, which requires frequent repairs and replacements, plastic shuttering does not warp, crack, or absorb chemicals, making it a low-maintenance and long-lasting investment.

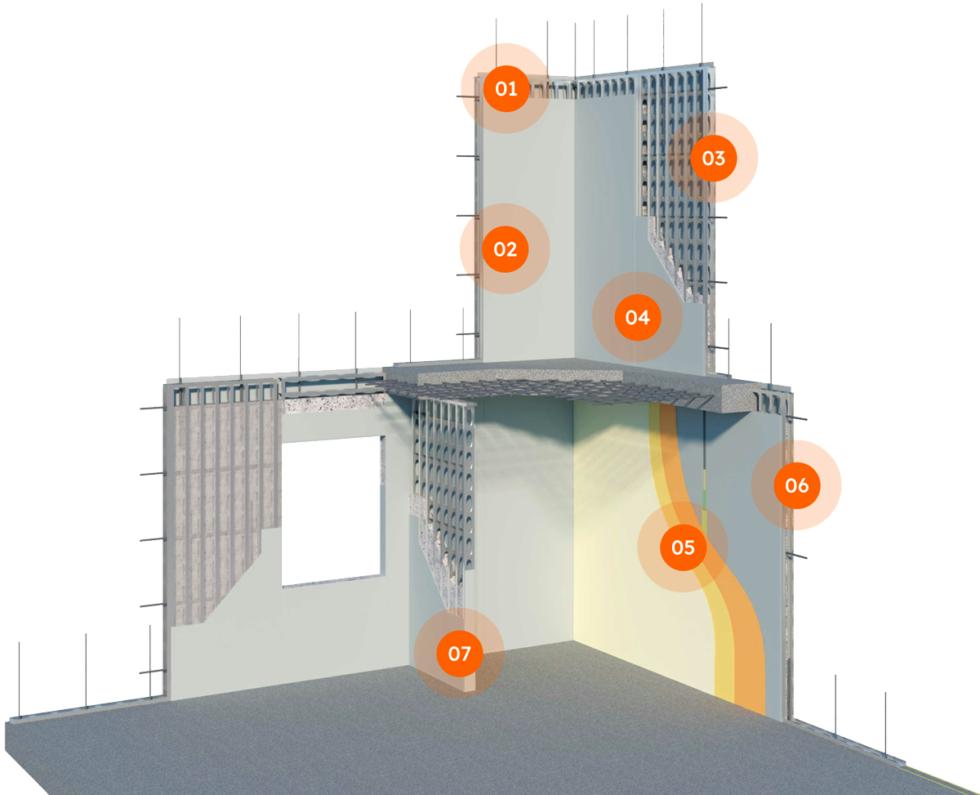

Applications of Plastic Shuttering in Construction

1. Residential and Commercial Buildings

Plastic shuttering is widely used in residential apartments, commercial office spaces, and high-rise buildings due to its cost efficiency and ease of use.

2. Infrastructure Projects (Bridges, Flyovers, and Roads)

Large-scale infrastructure projects require durable and reusable formwork, making plastic shuttering a perfect choice for bridges, flyovers, and roads.

3. Industrial and Factory Construction

Since plastic shuttering is resistant to chemicals and moisture, it is widely used in factories, warehouses, and industrial construction projects.

4. Modular and Temporary Structures

Plastic shuttering is also used for modular housing, emergency shelters, and temporary construction due to its quick installation and dismantling process.

Clearly, plastic shuttering is the superior choice for modern construction projects due to its high durability, cost savings, and sustainability.

How to Choose the Right Plastic Shuttering for Your Project

To get the best results from plastic shuttering, consider the following factors:

- Panel Size & Thickness – Select panels based on your project requirements.

- Load Capacity – Ensure the shuttering can handle the concrete pressure.

- Reusability & Storage – Store panels properly to maximize their lifespan.

- Brand & Quality – Choose high-quality plastic shuttering from a trusted manufacturer.

Conclusion: Why Choose Plastoform Solutions for Plastic Shuttering?

At Plastoform Solutions, we take immense pride in being a leading manufacturer of high-quality plastic shuttering solutions. With 15+ years of expertise, our state-of-the-art facility in Hyderabad is equipped with advanced technology to produce durable, cost-effective, and innovative plastic shuttering.

Our plastic shuttering is:

✔ Extremely durable and reusable

✔ Waterproof and weather-resistant

✔ Lightweight and easy to install

✔ Designed for all types of construction projects

By choosing Plastoform Solutions, you get unmatched quality, innovation, and value for your construction needs. Upgrade your projects with our premium plastic shuttering today!

📞 Contact Plastoform Solutions now to learn more!

Latest Blog

In the world of construction, the use of formwork is crucial for shaping and molding concrete structures

One of the primary advantages of plastic formwork is its high strength and durability. Made from..

When comparing plastic formwork with traditional formwork materials like plywood and steel...

Plastic formwork finds extensive application in various construction scenarios, offering..

Plastic formwork finds extensive application in various construction scenarios, offering..